Enhance IoT and Industry 4.0 with Diagram Digitization

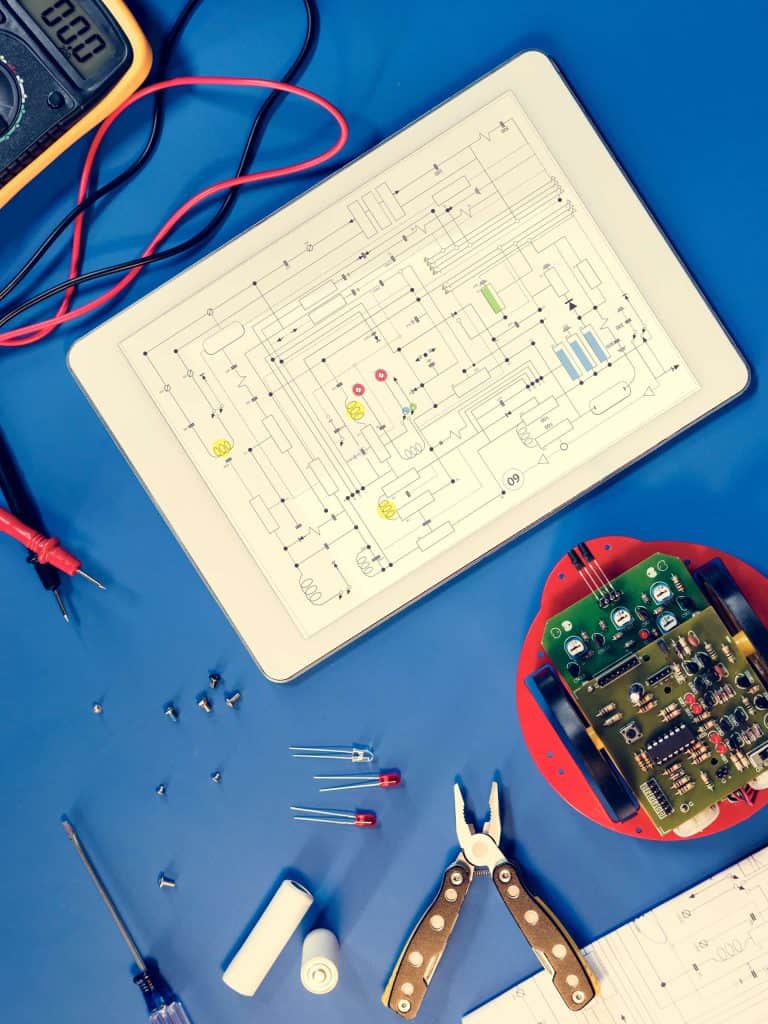

In the era of IoT and Industry 4.0, data insight is king and accurate data capture is crucial. At the heart of this endeavor lies the ability to capture the physical reality of facilities, equipment, and computer-controlled devices. This is where schematic drawings become invaluable. In this article, we explore how schematic drawings play a pivotal role in accurately representing physical reality, and how they can revolutionize the way we leverage data in IoT and Industry 4.0.

The Significance of Schematic Drawings in IoT and Industry 4.0:

Schematic drawings provide a visual representation that surpasses traditional textual information when it comes to visualizing complex systems. With their clear and concise format, schematic drawings enable efficient communication and understanding across various stakeholders. From sprawling manufacturing plants to intricate machinery, schematic drawings have proven to be instrumental in facilitating data-driven decision-making in Industry 4.0.

Standardizing Schematic Drawings:

Standardization is the key to harnessing the full potential of schematic drawings in IoT and Industry 4.0. Despite the challenges of navigating different industries and use cases, a common language for schematic drawings ensures seamless integration and interoperability. Having standardized schematic drawings allows businesses to make informed decisions based on accurate, consistent, and reliable data.

The Role of Schematic Drawings in Sensor Integration:

Localizing and understanding the placement and connections of sensors within a facility is critical to effective IoT implementations. Schematic drawings excel in providing a holistic view of sensor integration, enabling businesses to optimize sensor placements, monitor data flow, and enhance control over their IoT systems. By accurately representing sensor relationships, schematic drawings empower businesses to derive meaningful insights and take proactive measures in real-time.

Benefits of Diagram Digitization in IoT and Industry 4.0:

Diagram digitization offers several benefits for organizations embracing IoT and Industry 4.0. Let’s explore some of the key advantages:

1. Enhanced Data Visualization and Analysis:

By digitizing schematic drawings, organizations can leverage advanced data visualization and analysis techniques. Visualizations derived from digitized schematics enable data-driven professionals to explore complex systems, identify patterns, and uncover insights that might otherwise go unnoticed. These visualizations offer a deeper understanding of the relationships between components and how they interact in real-time.

2. Improved Collaboration and Communication:

Digitized schematic drawings can be easily shared across teams and departments, facilitating collaboration and effective communication. With digital representations accessible to all stakeholders, from engineers to project managers, organizations can minimize misunderstandings and streamline decision-making processes. This leads to improved coordination and more efficient workflows, ultimately enhancing productivity and reducing project timelines.

3. Streamlined Asset Management and Maintenance:

Digitized schematic drawings play a crucial role in asset management and maintenance within the realm of IoT and Industry 4.0. By integrating digitized schematics with data from IoT sensors and connected devices, businesses can gain real-time insights into the performance of their assets. This integration allows for proactive maintenance scheduling, reducing downtime and optimizing asset lifecycles. Additionally, historical data derived from digital schematics can be used for predictive maintenance, minimizing the risk of unexpected breakdowns and maximizing operational efficiency.

4. Data-Driven Decision Making and Optimization:

Digitized schematic drawings provide a solid foundation for data-driven decision making in IoT and Industry 4.0. By integrating data from digital schematics with other relevant data sources, organizations can gain a comprehensive view of their operations. This holistic view enables them to identify areas for optimization, implement process enhancements, and make informed decisions based on data-backed insights. With digitized schematics, companies have the potential to revolutionize their operations, from optimizing layouts and workflows to improving energy efficiency and resource allocation.

New Ideas: Beyond Traditional Schematic Drawings:

Integrating Digital Twin Databases:

One exciting innovation in schematic drawings is the concept of digital twin databases. By integrating schematic drawings with real-time data from IoT sensors, businesses can create dynamic representations of their physical assets. This integration allows for a deeper understanding and analysis of real-world performance, enabling companies to optimize operations and make data-driven decisions.

Augmented Reality (AR) and Virtual Reality (VR):

Schematic drawings combined with AR and VR technologies are transforming the way we interact with data. By overlaying schematic drawings onto the real world or immersing users into virtual environments, AR and VR provide enhanced visualization and contextual understanding. This enables data-driven professionals to explore complex systems, identify patterns, and make more informed decisions.

Benefits of Accurate Schematic Drawings in IoT and Industry 4.0:

Enhanced Maintenance and Predictive Analytics:

Accurate schematic drawings enable businesses to optimize maintenance schedules and predict equipment failures. By analyzing data captured through IoT sensors and overlaying it on schematic drawings, companies can identify potential issues, proactively schedule maintenance, and minimize downtime.

Improved Plant Cybersecurity:

Schematic drawings play a crucial role in strengthening vulnerability and threat assessments within plant cybersecurity. By visualizing the network infrastructure and identifying potential weak points and entry points for malicious actors, businesses can implement robust cybersecurity measures to safeguard their operations.

DataSeer's Approach to Schematic Drawing Digitization:

At DataSeer, we understand the transformative power of schematic drawings in capturing the physical reality for IoT and Industry 4.0. Our automated visualization software streamlines the extraction and digitization of data from schematic drawings, efficiently and accurately. Moreover, our user-driven approach enables businesses to tailor the output data schema format to their specific needs, providing the flexibility required in diverse industries and applications.

IoT and Industry 4.0: Powered by DataSeer

In the rapidly evolving landscape of IoT and Industry 4.0, schematic drawings offer a unique and essential tool for capturing the physical reality of facilities, equipment, and computer-controlled devices. Diagram digitization takes this concept to the next level by transforming physical schematics into digital assets that can be leveraged to unlock the power of data visualization and analysis. With DataSeer’s expertise in diagram digitization, businesses can harness the capabilities of advanced technologies to extract meaningful insights from their schematic drawings. Embrace the power of diagram digitization and join us in transforming industries through the innovative fusion of data and physical reality.