Where AI and Industrial Diagrams Meet

Over 88,000 pages of asset data processed.

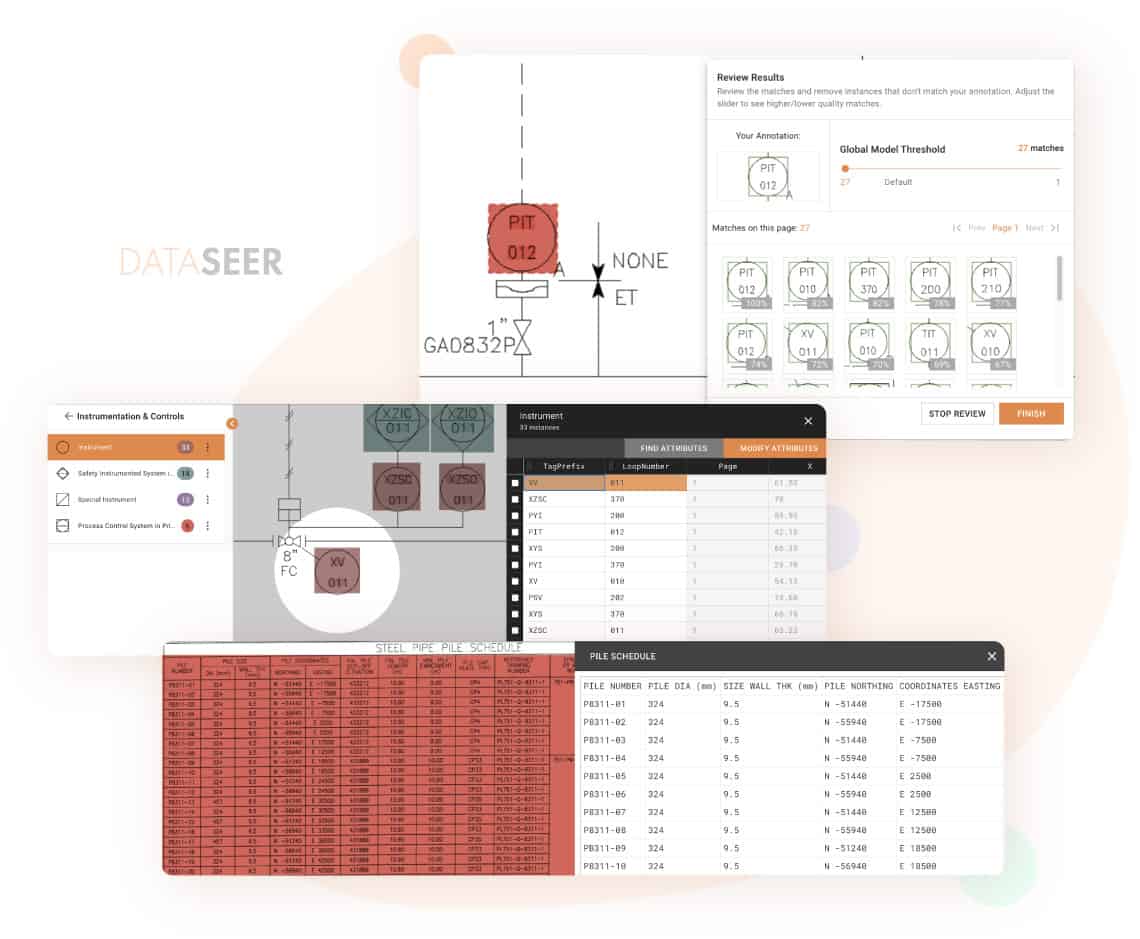

Analyze and extract the data you need from Diagrams & Datasheets

DataSeer provides automated visualization software that digitizes unstructured data trapped in 2D images and creates a digital twin database with API access.

Integrating industrial engineering with Machine Learning and Computer Vision, DataSeer facilitates rapid project turnaround, automates change management tracking, and reduces risks associated with the integration of legacy and greenfield processes.

Use DataSeer to...

Extract information that can be used across multiple use cases, including Asset Integrity Management, Plant Cybersecurity, Capital Projects Engineering & Estimating, Process Simulations, Plant Operations and Maintenance.

Some use cases:

- Rapidly estimate cost for planning, bidding, fabrication & construction

- Extract tabular data such as equipment lists, bill of materials and datasheets

- Convert legacy diagram images to digitized CAD drawing formats

Transforming the use of Industrial Drawings

We help teams do

their best work.

Leverage an AI-based asset data extraction tool like DataSeer to get unstructured data trapped in disparate industrial 2D flat images out in a high-fidelity digitized format.

Why users love DataSeer

Drive revenue with faster project turnaround & onboarding

Increase ROI by up to 10x

Minimize cost overruns associated with change management

Reduce costs from laborious error-prone manual efforts

Increase quality control with always-on, accurate database of process & asset data

Decrease liability by minimizing risk from errors & omissions

Key Benefits

Off-the-shelf application, no setup or configuration

User-centric design that's easy & intuitive to use

Use our default P&ID symbol library or build your own!